Value stream mapping-gold analysis at Anglogold Ashanti in Ghana

Introduction

In the competitive landscape of the mining and minerals industry, efficiency, accuracy, and data reliability are critical success factors. For gold laboratories, every step of the analytical process directly impacts profitability. Inefficiencies in workflow or errors in assay data can translate into significant financial losses.

This is where Value Stream Mapping (VSM) becomes a powerful tool. By systematically visualizing the entire gold assay workflow, VSM identifies inefficiencies, reduces waste, and drives continuous improvement.

With over a decade of experience in laboratory management, ISO17025 implementation, and process optimization, Makumba Musambachime, Mineral Lab Consultant shares practical insights on applying Value Stream Mapping to enhance laboratory performance in gold analysis.

What Is Value Stream Mapping?

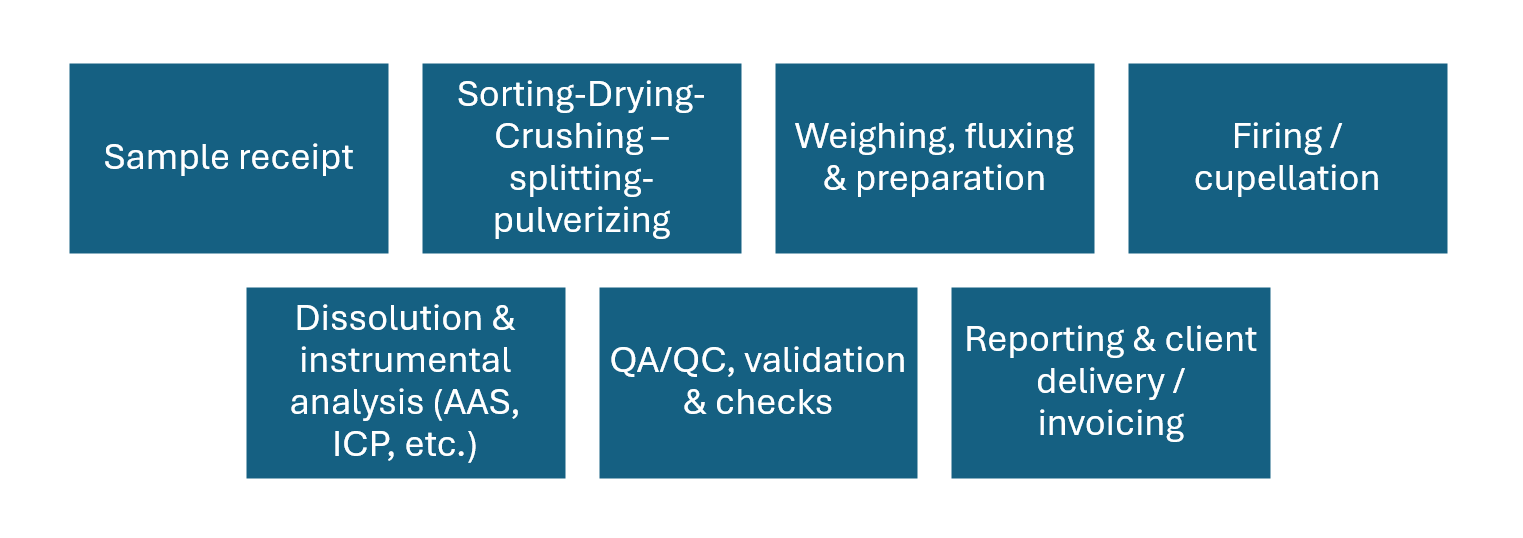

Value Stream Mapping is a lean management technique used to visualize and analyze every step involved in a process—from input to output. In a gold assay laboratory, this involves mapping each stage of the Fire Assay (FA) workflow, identifying where value is added and where waste occurs.

The goal is simple:

- Maximize value-added activities such as accurate data generation.

- Eliminate non-value-added steps such as delays, redundant manual entries, and excessive material handling.

By understanding the entire value chain, laboratories can achieve higher throughput, improved quality control, and better cost efficiency.

Why Value Stream Mapping Matters in Gold Analysis

Gold is not just a commodity—it is a high-value asset. The precision of analytical results determines the accuracy of mine reconciliation and overall profitability. Even minor assay discrepancies can lead to reconciliation penalties, costing operations hundreds of thousands of dollars.

Applying VSM principles ensures that every process step contributes meaningfully to value creation, while inefficiencies are systematically reduced or removed.

Mapping the Gold Assay Workflow

A comprehensive Value Stream Map for gold analysis highlights both the value-added and non-value-added components of the assay workflow. Common waste areas include:

- Manual data entry and transcription errors

- Unnecessary sample waiting times

- Inefficient laboratory layout and equipment placement

- Excessive quality control checks without actionable insights

Addressing these issues through workflow redesign and digital integration results in measurable improvements in turnaround time and data accuracy.

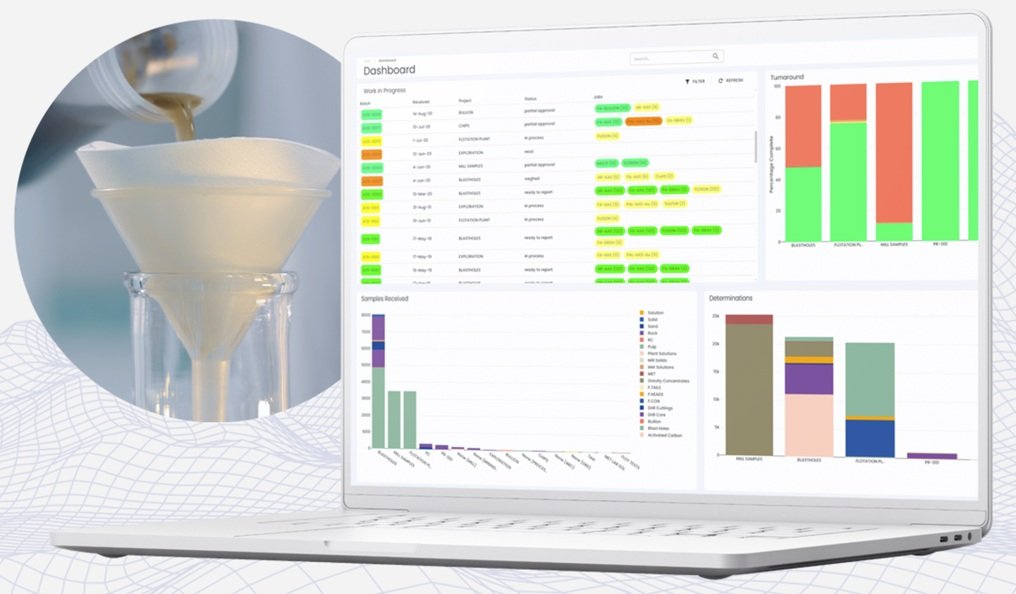

Case Study: LIMS Implementation at Bisha Mine

At Bisha Mine, the introduction of a Laboratory Information Management System (LIMS – Assaynet) significantly enhanced operational efficiency. By eliminating manual data entry and automating quality control dashboards, the laboratory achieved:

- Over $1 million in savings from reduced reconciliation penalties

- Enhanced accuracy and traceability of results

- Streamlined quality control monitoring

The LIMS implementation became a core value driver, transforming laboratory operations from reactive management to proactive optimization.

Reinventing the Laboratory’s Core Focus

The primary mission of any analytical laboratory is to deliver accurate data for informed decision-making. Through the integration of VSM and LIMS, laboratories can shift their focus from administrative oversight to data-driven quality management.

The result is a lean, agile, and reliable laboratory environment where teams focus on continuous improvement and strategic value delivery.

Additional Value-Enhancement Strategies

Beyond digital transformation, operational optimizations can further improve lab efficiency and profitability:

- Optimized Fusion Time: Adjusting parameters based on ore mineralogy and sulphur content reduced fusion times by up to 20 minutes, increasing daily throughput.

- Laboratory Layout Redesign: Strategic repositioning of key equipment minimized movement and reduced sample turnaround times.

Adoption of New Methods: Exploring alternatives such as cold block digestion and photon assay enables future-ready operations aligned with industry trends.

Evolving Gold Analysis Technologies

While Fire Assay remains the industry standard for accuracy, it presents challenges due to the use of lead, which poses health and environmental risks.

Emerging XRF-based methods such as Photon Assay and DetectOre are gaining traction for their ability to deliver results faster, safely, and with comparable precision.

The shift toward these technologies is driven by:

- Faster analysis turnaround

- Improved safety standards

- Commitment to sustainability and operational efficiency

Value Stream Implementation Roadmap

A structured roadmap ensures successful implementation of Value Stream Mapping in laboratory operations:

- Map current workflows and identify process bottlenecks.

- Classify steps as value-added or waste.

- Set measurable performance targets for improvement.

- Integrate digital tools such as LIMS and automated QC systems.

- Monitor, evaluate, and refine continuously for sustained results.

This roadmap ensures that process improvements are not only implemented but also maintained over time.

Conclusion

The application of Value Stream Mapping in gold laboratories represents a strategic approach to achieving operational excellence. By combining process analysis, digital transformation, and continuous improvement, laboratories can enhance both data integrity and profitability.

As the gold analysis industry evolves, embracing lean methodologies and emerging technologies will be key to maintaining efficiency, safety, and competitive advantage.

For laboratories committed to precision, sustainability, and innovation, Value Stream Mapping is not just an improvement tool, it is a roadmap to long-term success.